IPD: Manta Ray Desk Candy

The first major project of my Integrated Computer-Aided Design course was to design and machine an aesthetically-pleasing piece of "desk candy" using 3D milling software.

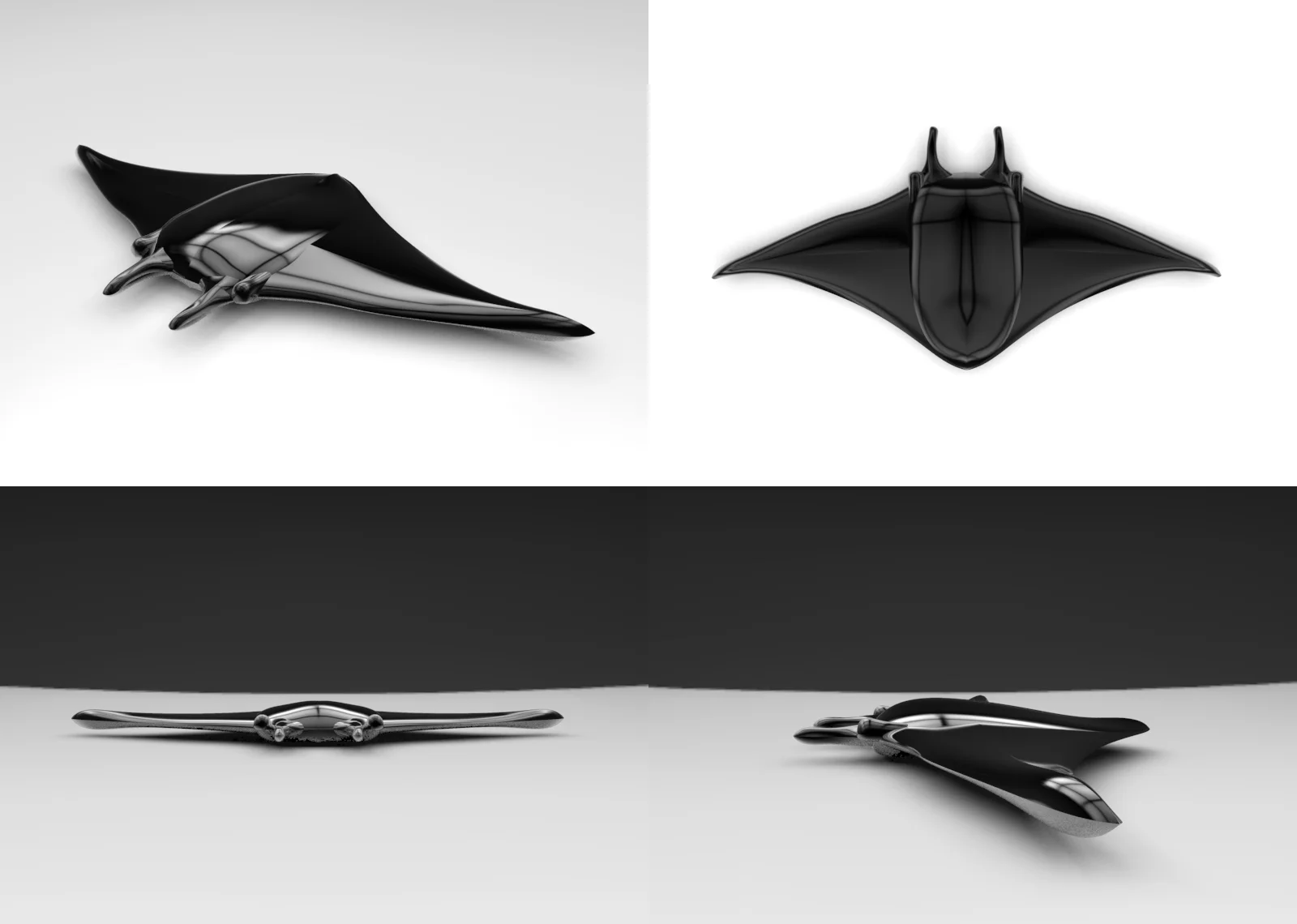

This was my introduction to 3D computer aided machining software. To make full use of the 3D capabilities of a 3-axis milling machine, I decided to make a Manta ray. The curving, organic surfaces of Manta ray present geometries that are otherwise impossible to achieve with the 2.5-D milling processes. Additionally, the flat and wide features of a Manta ray allowed for fast-machining and efficient use of material.

The geometry was designed in such a way that only 3 tools (0.5" square mill, 0.25" ball mill, 1/16" ball mill) were required to complete all operations.

All machining operations were programmed using SolidCAM.

The geometry of the Manta ray designed in SolidWorks, with all the aesthetic features being surface modeled.

The various surfaces were knitted together and filled into a single solid body, which was then referenced in SolidCAM.

The geometry of the Manta ray was divided into two sides. The G-code executed the machining operations one side at a time on a Haas 3-axis Minimill.

Precise fixture was required to ensure a minimal part line due to the two part machining process.